Qingdao Hyperway International Trade

Grooved rigid couplings are mainly used to connect steel pipes for fire protection system, potable water supply system, municipal construction, mine, chemical factory and other occasions when steel pipes used.

Material of body: ductile cast iron (ASTM A536,Grade: 65-45-12)

Material of gasket: EPDM, NBR, silicon rubber

Standard: UL213

Working pressure: 2.07MPa / 300PSI

Surface treatment: electrostatics powder painting, galvanization

Colors: RAL3000, blue, white or as customized

Bolts and nuts: stainless steel, grade 8.8

All sizes are UL listed and FM approved

Product parameters

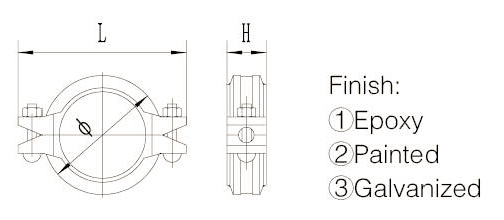

| Nominal size | Pipe OD | Working Pressure | Product Dimension (inch / mm) | Bolt/Nut | ||

| inch / mm | inch / mm | PSI / MPa | Φ | L | H | |

| 1 25 | 1.327 33.7 | 300 2.07 | 2.205 56 | 3.78 96 | 1.772 45 | 10*45 |

| 1 1/4 32 | 1.669 42.4 | 300 2.07 | 2.598 66 | 4.173 106 | 1.772 45 | 10*45 |

| 1 1/2 40 | 1.9 48.3 | 300 2.07 | 2.835 72 | 4.488 114 | 1.772 45 | 10*45 |

| 2 50 | 2.375 60.3 | 300 2.07 | 3.189 81 | 4.961 126 | 1.85 47 | 10*55 |

| 2 1/2 65 | 2.875 73 | 300 2.07 | 3.74 95 | 5.472 139 | 1.85 47 | 10*55 |

| 3 (OD) 65 | 3 76.1 | 300 2.07 | 3.898 99 | 5.63 143 | 1.85 47 | 10*55 |

| 3 80 | 3.5 88.9 | 300 2.07 | 4.409 112 | 6.181 157 | 1.89 48 | 10*55 |

| 4 100 | 4.5 114.3 | 300 2.07 | 5.433 138 | 7.598 193 | 1.969 50 | 12*65 |

| 5 1/2 (OD) 125 | 5.5 139.7 | 300 2.07 | 6.535 166 | 8.701 221 | 1.969 50 | 12*70 |

| 5 125 | 5.563 141.3 | 300 2.07 | 6.654 169 | 8.74 222 | 1.969 50 | 12870 |

| 6 1/2 (OD) 150 | 6.5 165.1 | 300 2.07 | 7.598 193 | 9.843 250 | 2.008 51 | 12*70 |

| 6 150 | 6.625 168.3 | 300 2.07 | 7.717 196 | 10.079 256 | 2.008 51 | 12*70 |

| 8 200 | 8.625 219.1 | 300 2.07 | 10 254 | 12.677 322 | 2.48 63 | 16*85 |

| 10 250 | 10.75 273 | 300 2.07 | 12.323 313 | 15.433 392 | 2.52 64 | 20*100 |

| 12 300 | 12.75 323.9 | 300 2.07 | 14.409 366 | 17.52 445 | 2.598 66 | 20*110 |

Product parameters

| Nominal size | Pipe OD | Working Pressure | Product Dimension (inch / mm) | Bolt/Nut | ||

| inch / mm | inch / mm | PSI / MPa | Φ | L | H | |

| 1 25 | 1.327 33.7 | 300 2.07 | 2.205 56 | 3.78 96 | 1.772 45 | 10*45 |

| 1 1/4 32 | 1.669 42.4 | 300 2.07 | 2.598 66 | 4.173 106 | 1.772 45 | 10*45 |

| 1 1/2 40 | 1.9 48.3 | 300 2.07 | 2.835 72 | 4.488 114 | 1.772 45 | 10*45 |

| 2 50 | 2.375 60.3 | 300 2.07 | 3.189 81 | 4.961 126 | 1.85 47 | 10*55 |

| 2 1/2 65 | 2.875 73 | 300 2.07 | 3.74 95 | 5.472 139 | 1.85 47 | 10*55 |

| 3 (OD) 65 | 3 76.1 | 300 2.07 | 3.898 99 | 5.63 143 | 1.85 47 | 10*55 |

| 3 80 | 3.5 88.9 | 300 2.07 | 4.409 112 | 6.181 157 | 1.89 48 | 10*55 |

| 4 100 | 4.5 114.3 | 300 2.07 | 5.433 138 | 7.598 193 | 1.969 50 | 12*65 |

| 5 1/2 (OD) 125 | 5.5 139.7 | 300 2.07 | 6.535 166 | 8.701 221 | 1.969 50 | 12*70 |

| 5 125 | 5.563 141.3 | 300 2.07 | 6.654 169 | 8.74 222 | 1.969 50 | 12870 |

| 6 1/2 (OD) 150 | 6.5 165.1 | 300 2.07 | 7.598 193 | 9.843 250 | 2.008 51 | 12*70 |

| 6 150 | 6.625 168.3 | 300 2.07 | 7.717 196 | 10.079 256 | 2.008 51 | 12*70 |

| 8 200 | 8.625 219.1 | 300 2.07 | 10 254 | 12.677 322 | 2.48 63 | 16*85 |

| 10 250 | 10.75 273 | 300 2.07 | 12.323 313 | 15.433 392 | 2.52 64 | 20*100 |

| 12 300 | 12.75 323.9 | 300 2.07 | 14.409 366 | 17.52 445 | 2.598 66 | 20*110 |

If you have any questions about the product, please fill in the form below and we will contact you as soon as possible