Qingdao Hyperway International Trade

Cast iron pipes are made of cast grey iron complying with ISO185 grade 150, they are widely used for drainage in high-rise buildings because they are solid and durable with excellent noise suppression, fire resistance, low thermal expansion and chemical resistance. They are also easy to be installed by couplings or clamps.

Centrifugal cast iron pipe system comprises non-hub pipes, non-hub fittings, joints(couplings or clamps) and accessories. It’s an ideal and economical building drainage system because of the above advantages.

Material of pipe body: cast iron

Inner coating: coking bituminous or epoxy resin paint

Outer coating: anti-rusting paint or epoxy resin paint

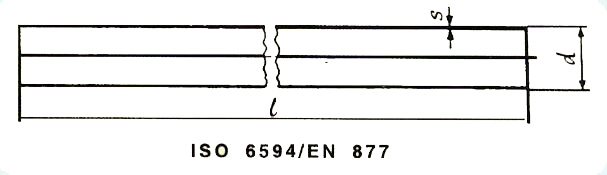

Manufacturing standard: ISO6594 & EN877

Manufacturing method: centrifugal casting

Connection: couplings or clamps joining

Product parameters

Length: 3000mm + 20mm

| DN mm | Outside diameter d (mm) | Wall thickness s (mm) | Packing | ||

| Nominal size | Tolerance | Nominal size | Min. | pcs/pallet | |

| 40 | 48 | +2 -1 | 3.0 | 2.5 | 68 |

| 50 | 58 | 3.5 | 3.0 | 50 | |

| 70 | 78 | 3.5 | 3.0 | 50 | |

| 75 | 83 | 3.5 | 3.0 | 46 | |

| 100 | 110 | 3.5 | 3.0 | 34/38 | |

| 125 | 135 | +2 -2 | 4.0 | 3.5 | 20 |

| 150 | 160 | 4.0 | 3.5 | 17 | |

| 200 | 210 | +2.5 -2.5 | 5.0 | 4.0 | 10 |

| 250 | 274 | 5.5 | 4.5 | 8 | |

| DN mm | Outside diameter d (mm) | Wall thickness s (mm) | Packing | ||

| Nominal size | Tolerance | Nominal size | Min. | pcs/pallet | |

| 40 | 48 | +2 -1 | 3.0 | 2.5 | 68 |

| 50 | 58 | 3.5 | 3.0 | 50 | |

| 70 | 78 | 3.5 | 3.0 | 50 | |

| 75 | 83 | 3.5 | 3.0 | 46 | |

| 100 | 110 | 3.5 | 3.0 | 34/38 | |

| 125 | 135 | +2 -2 | 4.0 | 3.5 | 20 |

| 150 | 160 | 4.0 | 3.5 | 17 | |

| 200 | 210 | +2.5 -2.5 | 5.0 | 4.0 | 10 |

| 250 | 274 | 5.5 | 4.5 | 8 | |

If you have any questions about the product, please fill in the form below and we will contact you as soon as possible